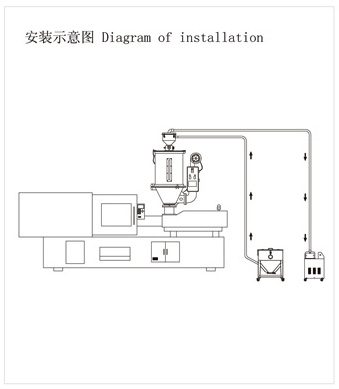

The heating barrel is made from the stainless steel to ensure that the material is not polluted and easier to be cleaned. The air dispersion device of the stainless steel net plate enables the heat air to evenly blow the material. The temperature is even in the barrel and the material sinters on time. There is a hinge connection structure between the heating barrel and the hopper, which facilitates opening, reloading and cleaning. An open-door type magnetic base, which is convenient and easy to take out the magnet for cleaning the scrap iron. The timing startup device of any time can be matched to reduce pre-heating time on duty and improve efficiency. The hot air recycler device can be matched to reduce energy consumption. The Hopper dust collector can be matched to prevent the dust into the workshop.